I was surprised to find issues in regard to track compatibility as I started to install track in the Wheeling Freight Terminal staging yard. I was using Walthers/Shinohara track switches and Atlas flex track. All were code 83 rail, but there was something amiss.

Tie Thickness

The National Model Railroad Association (NMRA) has many standards and recommended practices that are used across the model railroad industry so our models can operate using components from different manufacturers. Specific rail, gauge and track switch tolerances are outlined across several standards at the NMRA website. One aspect that is not standardized is the thickness of the ties that support the rails. As I am using up lots of accumulated materials with this project, I’ve encountered a tie thickness discrepancy. Click on the next two images for larger versions.

I have accumulated lots of Atlas code 83 flex track as well as several sections of Shinohara code 83 flex track bought at swap meets and train shows over the years. I am using the Walthers/Shinohara track switches on this project and the overall tie and rail height matches the older Shinohara track, but not the Atlas flex track. The height difference is about 0.030 inches. Many people may not worry about a thity-thousandsths of an inch difference, but it is noticable when you push a string of freight cars across an uneven rail joint. Steam locomotives would have some difficulty smoothly operating over the same joint. This situation becomes a problem to solve.

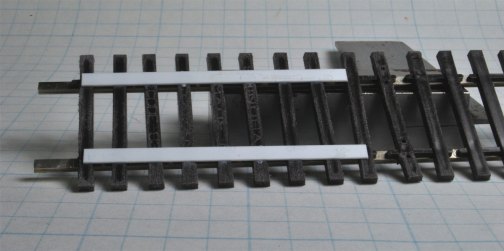

I made transition sections of five to six inch long Shinohara track sections by adding styrene shims under the ties. After prepping the rails on each end, the bottom of the ties on the last two inches of these short track sections are sanded to remove the slick, glossy surface. HO scale 2×10 styrene strip shims are cut two inches long and glued onto the ties under the rails. Once the joint is dry, the shims are carefully sanded to make a slight taper. After blowing the dust away, the shims are carefully painted with Rail Brown to hide their presence. I did not have any grey or black styrene on hand for this project. Here’s a transition section before painting.

When the transition section is complete, it is soldered to a piece of the Atlas code 83 flex track with the shimmed end close to the rail joint. After the flux is cleaned off of the solder joint, a mill file is used to remove any slight bump at the rail joint. Some people may feel a slight taper can be done by sanding the Atlas flex track ties, but without a belt sander at hand I feel these transition sections do the job.

After creating several of these short transition pieces, a friend suggested another method that is much less involved. I’ll cover that in the next post.

I welcome your comments here. Comments are reviewed and approved before they appear here.

Have the same problem on my switching layout. Using Peco flextrack and Walthers turnouts. I’m thinking I might just shim the entire turnout and then cover with dirt/ballast.

It is such the bother, eh Eric? I will be posting another method of shimming track this weekend that you may find interesting. I hope to post on Saturday morning. It’s a simpler method than what I described here.

– Eric

Eric

I find your blog interesting. I am also planning a layout that deals with Wheeling and Benwood although free lanced. One of the things I will be including will be a “standin” model for the Wheeling Freight house. I am originally from Wheeling and lived there till about 1994 when I moved to Texas. One of the things I picked up from ohio county library’s web site was the polk map of wheeling around 1906 if I remember correctly.

I would be real interested in your track plan I did not see a link to it in your blog and I just did discover your blog so have not searched completely. Just on the other side of the creek from your freight house was a small yard and a grocery supply building called CA Robrects, that building is nearly a dead ringer for the one in the Walthers catalog that is called a grocery supply or something. The large building with the water tower in your second picture had a track running into it and it was Robrects Warehouse and was later bought buy Boury Inc. and is presently used for storage according to goggle earth.

I now live in East Texas since you have my email above send me a email and we may exchange info and possibly I’ll see you at either the Fort Worth or Plano train show this year, my club is part of the council that works on these shows.

Welcome aboard, Rob! It’s great to find someone else with an interest in the Wheeling, WV rails. I think we have much to share and learn, I just wish Fort Worth wasn’t a 12 hour drive from El Paso! I look forward to more discussion soon.

– Eric